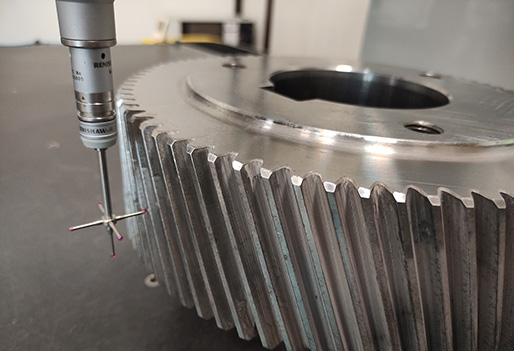

Reverse engineering of various gears using modern GEAR DATA methods and achieving very high accuracy

Extraction of correction coefficients and MODIFICATIONS of gears such as TIP RELIEF - CROWNING OF LEAD & PROFILE-HELIX MODIFICATION

Determination of gear grade and gear graph according to DIN, AGMA, ISO standards

Measurement of helical and spur gears (HELICAL GEAR) based on standards

Measurement of worm gears (WORM GEAR) based on DIN 3974 standard

Measurement of bevel gears (BEVEL GEAR), comparison of the production sample profile with the master sample

Measurement and monitoring of hob manufacturing, and control of tool error, pressure angle, and tool pitch