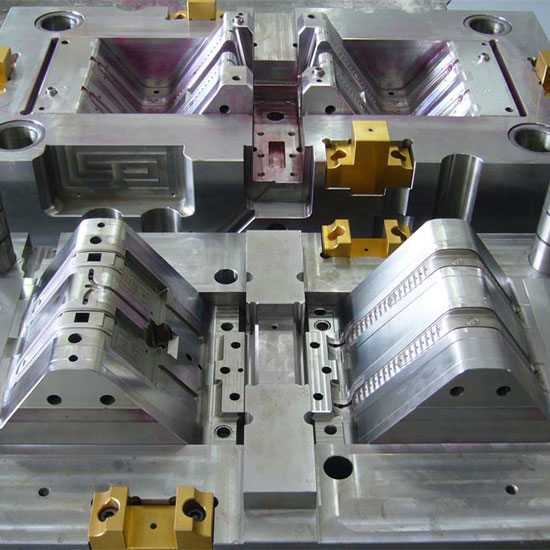

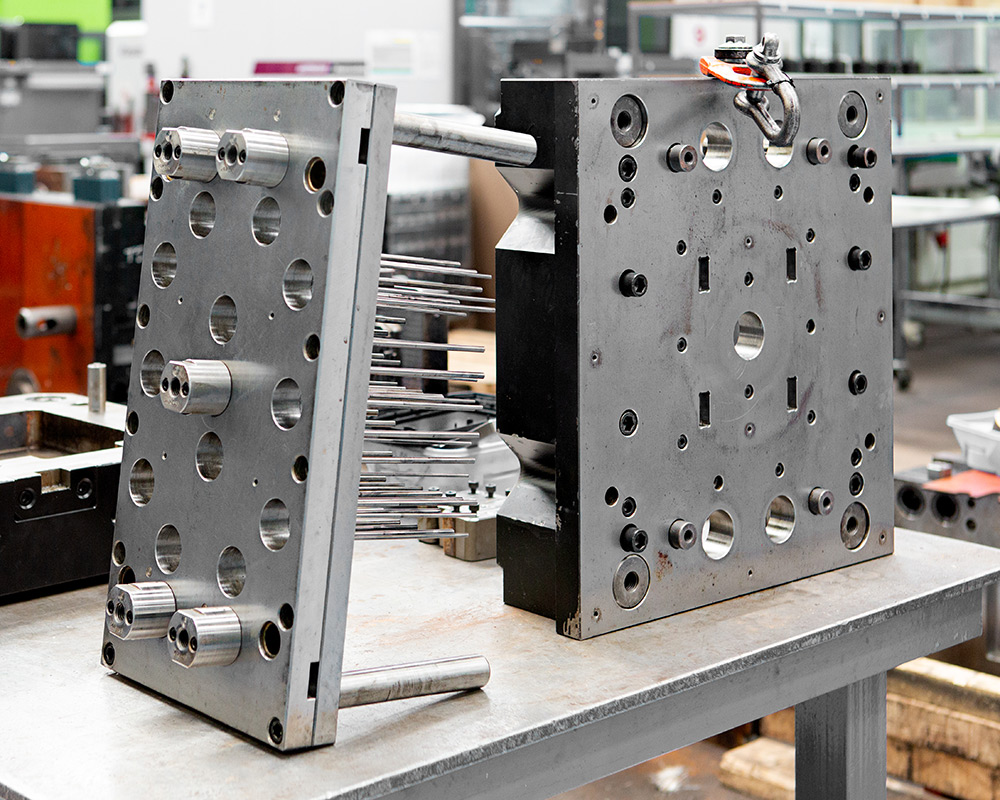

Equipped with both fixed and portable 3D scanners and a highly skilled design team, all models are first developed using advanced CAD software. Molds are then designed using specialized casting simulation tools such as ProCAST, allowing for optimal gating and feeding system layouts.

Our mold design and manufacturing services include:

-

Design and production of small- to medium-sized plastic injection molds

- Part design using 3D scanning and advanced modeling software

- Custom mold manufacturing for injection of materials such as PP, Polyamide, and more

- Production of gearbox cap molds for the hygiene and food industries

- Molds for material separation nozzles used in the food processing industry

- Corrugated pipe mold manufacturing for water and wastewater industries

- Mold production for EPS (Styrofoam) packaging applications

- Design and manufacturing of various casting molds (plate-type and free-form), including the use of modern techniques such as 3D printing

- Production of gearbox and pump housings (casings)

- Manufacturing of open and closed impellers

- Fabrication of components for the oil and gas industry such as valves, housings, and more

- Production of parts for construction machinery, including carriers, mounts, manifolds, and more